Unlocking the Potential of Прецизионная Механическая Обработка

In the world of advanced manufacturing, прецизионная механическая обработка stands as a cornerstone for creating components that demand utmost accuracy and reliability. This process involves using sophisticated techniques to shape materials with micron-level precision, ensuring that every detail meets stringent specifications. At DEPU CNC (Shenzhen) Co., Ltd., we specialize in delivering top-tier прецизионная механическая обработка solutions that empower industries like aerospace, automotive, and electronics to achieve superior performance. Our commitment to excellence, backed by over 20 years of expertise, allows us to produce parts that not only function flawlessly but also stand the test of time.

Essential Оборудование для Прецизионной Обработки

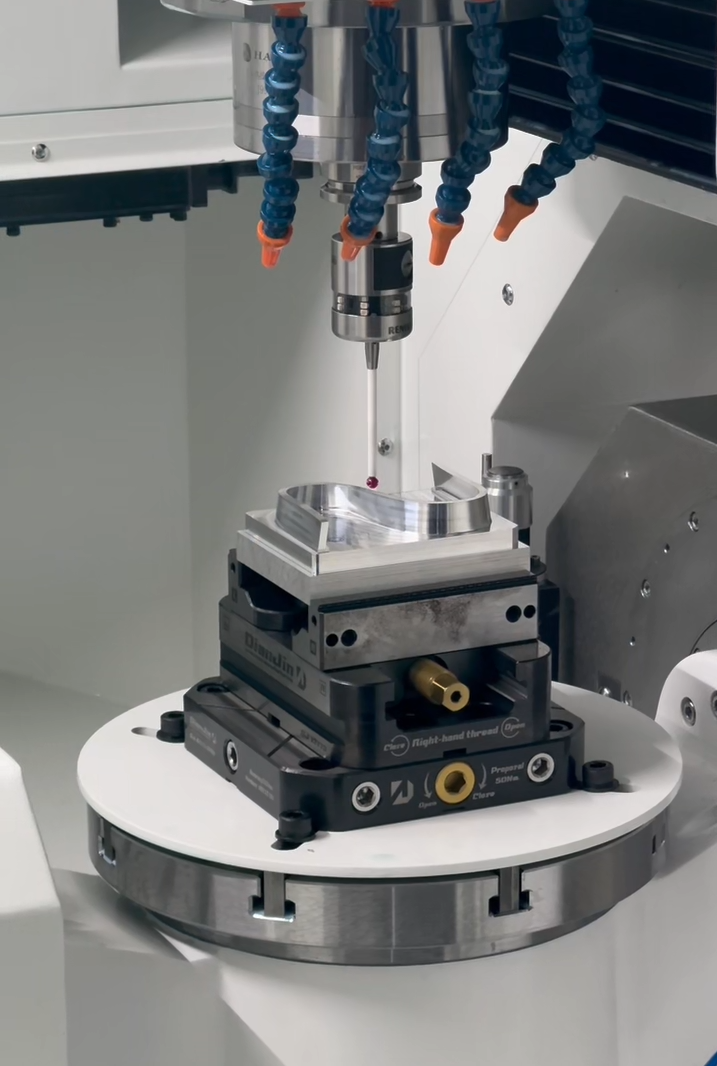

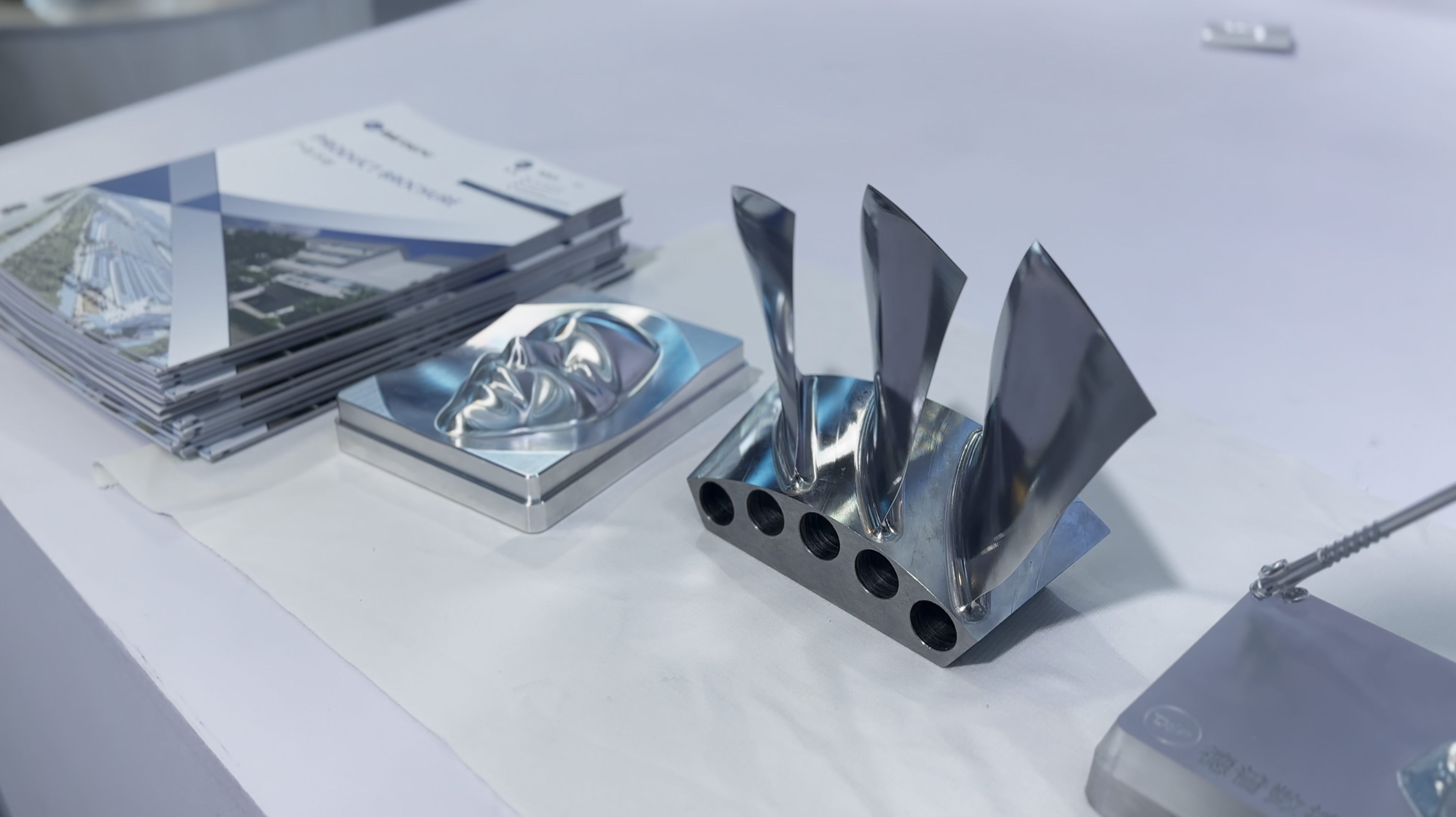

When it comes to executing прецизионная механическая обработка, the right оборудование для прецизионной обработки is paramount. DEPU's AIRCPHANE 202 BSC-54 NC machine exemplifies this, featuring a cutting-edge CNC system that automates machining with unparalleled repeatability. This equipment handles everything from milling to drilling, producing прецизионные детали with mirror-like finishes that reduce friction and enhance efficiency. For instance, in crafting high-performance turbocharger compressor wheels, our оборудование для прецизионной обработки ensures intricate blade designs that optimize airflow and boost engine power. With features like high-speed spindles and Zeiss-validated precision, DEPU guarantees stability in heavy-duty operations, making our solutions ideal for clients including Fortune Global 500 companies.

Услуги Прецизионной Механической Обработки Tailored to Your Needs

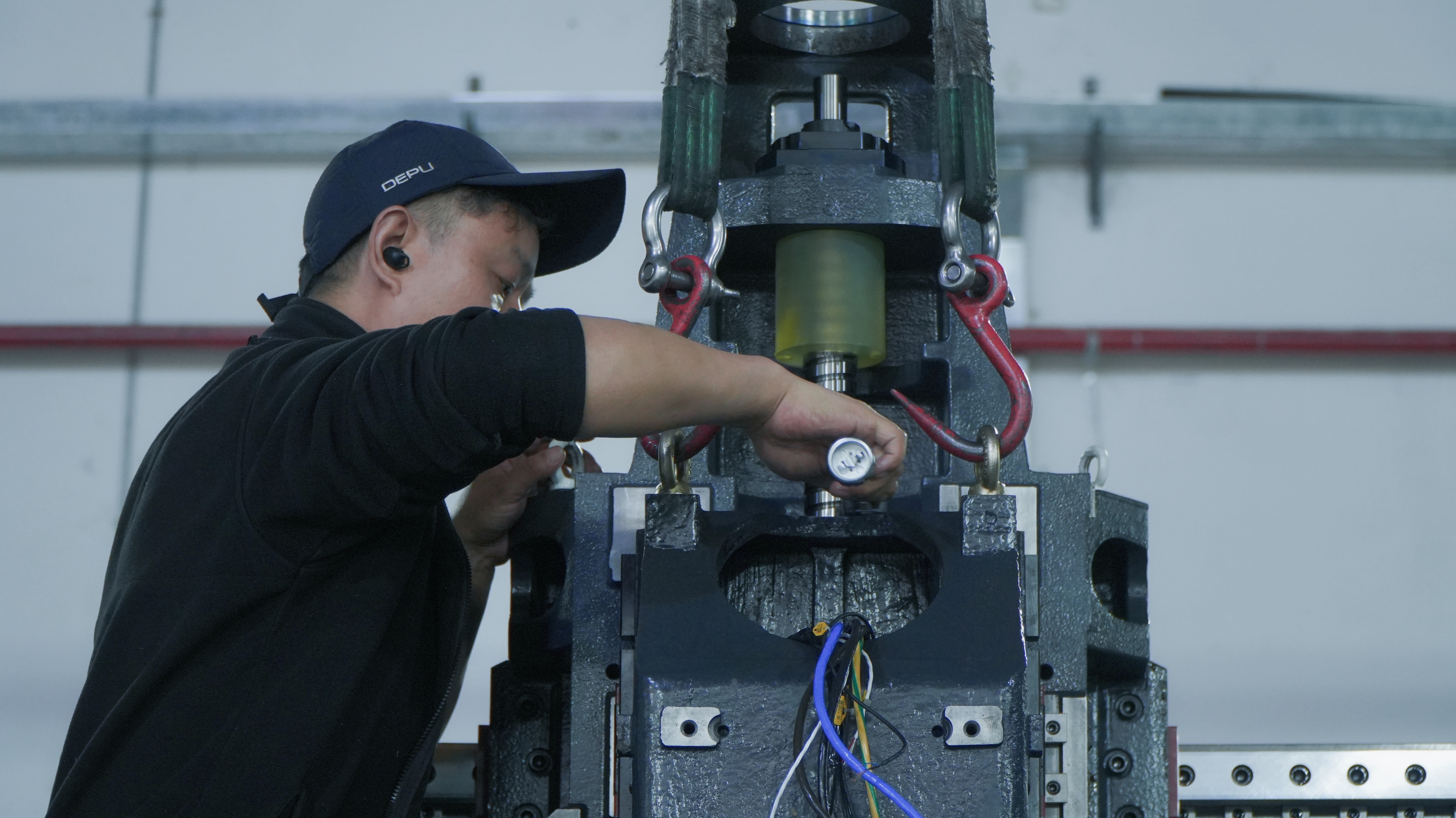

DEPU CNC offers comprehensive услуги прецизионной механической обработки, from prototyping to full-scale production, all under end-to-end process control. Our услуги прецизионной механической обработки include custom industrial solutions that integrate advanced technology for seamless manufacturing. Whether you're in need of прецизионные детали for 3C accessories or auto parts, our team provides free custom fixture design and operational training to minimize setup times and maximize productivity. This personalized approach has earned us trust from renowned clients, serving 2 Fortune Global 50 and 9 publicly listed companies. By leveraging our услуги прецизионной механической обработки, businesses can achieve high-tolerance components that meet safety and performance standards in demanding environments like ship equipment.

Методы Прецизионной Механической Обработки for Complex Challenges

Exploring методы прецизионной механической обработки reveals a blend of innovation and precision. At DEPU, we employ методы прецизионной механической обработки such as CNC milling and turning, optimized for фрезерование прецизионных деталей. These methods allow for the creation of complex geometries in прецизионные детали, ensuring durability under extreme conditions. For example, our G500 and V866U machine tools, introduced in 2022, facilitate высокоточная механическая обработка that extends equipment lifespan by over 30%. Combined with technologies like our third-generation encoder in 2025, these методы прецизионной механической обработки reduce errors and enhance surface quality, making them perfect for механическая обработка на заказ in automotive turbochargers.

Advancing with Технологии Прецизионной Обработки

The evolution of технологии прецизионной обработки is driving the future of manufacturing, and DEPU is at the forefront. Our технологии прецизионной обработки incorporate intelligent software and robust builds to handle обработка сложных деталей with ease. From the Depu-MasterLink automation system launched in 2023 to the enhanced U series in 2024, these advancements ensure reliable performance in high-stakes applications. For фрезерование прецизионных деталей in electronics or marine components, our технологии прецизионной обработки deliver corrosion-resistant, high-precision results. By partnering with DEPU, you gain access to turnkey solutions that include CNC programming and prototyping services, all validated by rigorous CMM inspections. This not only boosts efficiency but also positions your operations ahead in competitive markets.

Why Choose DEPU for Высокоточная Механическая Обработка

Selecting DEPU for высокоточная механическая обработка means investing in a partner dedicated to innovation and quality. Our history, founded in 2021 with a team boasting 20+ years of R&D, underscores our philosophy of excellence inspired by the Tao Te Ching. We provide comprehensive support, from foundation planning to advanced integration, ensuring your production lines thrive. For обработка сложных деталей like aerodynamic compressor wheels, DEPU's высокоточная механическая обработка guarantees lightweight yet strong constructions using aircraft-quality materials. With certified quality and a track record of serving global leaders, we transform challenges into opportunities, elevating your manufacturing to new heights of precision and efficiency.

In summary, прецизионная механическая обработка is more than a process—it's the gateway to superior engineering. At DEPU CNC, we invite you to explore how our expertise in оборудование для прецизионной обработки, услуги прецизионной механической обработки, and cutting-edge технологии прецизионной обработки can revolutionize your projects. Contact us today to discover tailored solutions for your прецизионные детали needs.