Understanding 5-Axis Machining

5-axis machining represents a cornerstone in modern manufacturing, enabling the simultaneous movement of tools along five axes for unparalleled precision and efficiency. This advanced technique, often referred to as 5-осевая обработка in technical circles, allows for the creation of complex geometries that traditional methods simply cannot achieve. At DEPU CNC (Shenzhen) Co., Ltd., we specialize in delivering cutting-edge solutions that harness this technology to meet the demands of industries worldwide. With over 20 years of expertise in machine tool R&D, our company has empowered Fortune 500 clients to elevate their production capabilities.

Key Components of Metalworking in 5-Axis Processing

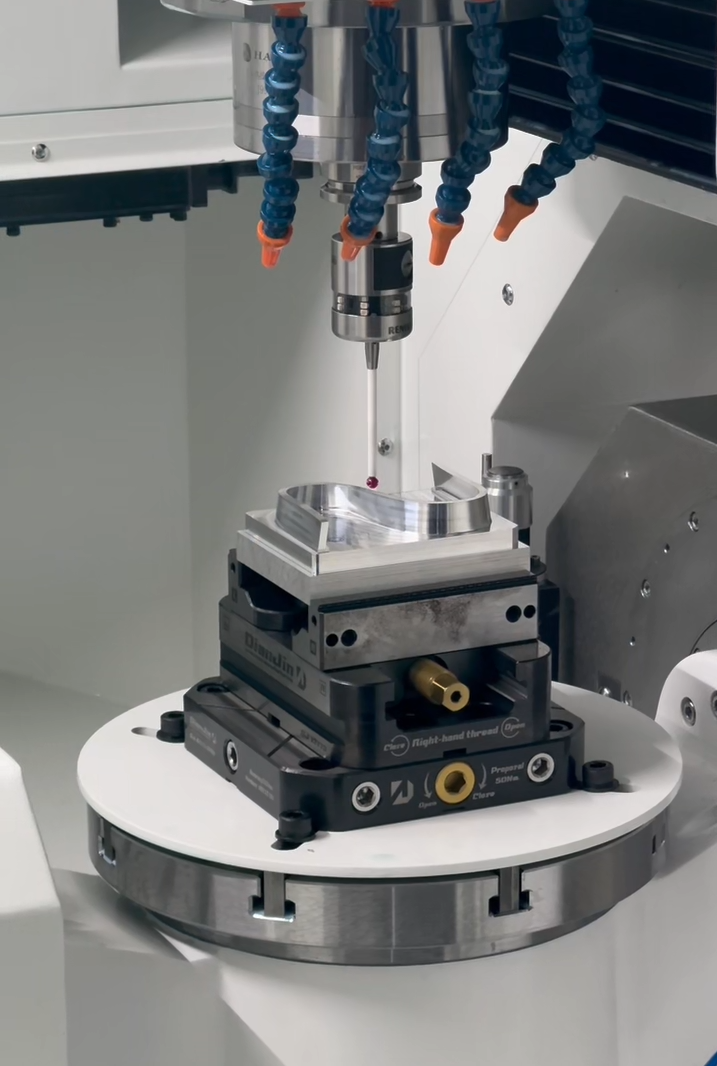

When it comes to metalworking 5-axis, the process involves sophisticated equipment like фрезерные 5-осевые станки, which are designed to handle intricate cuts and contours on metal parts. These 5-axis machines rotate and tilt the workpiece or tool, providing access to multiple angles in a single setup. This reduces the need for repositioning, minimizing errors and saving time. DEPU's state-of-the-art CNC machining centers feature high-speed spindles and advanced servomotors, ensuring stability even during heavy-duty operations. Our machines, validated by Zeiss CMM inspections, guarantee accuracy down to micrometers, making them ideal for applications in aerospace and automotive sectors.

Applications in 3D and Precision Machining

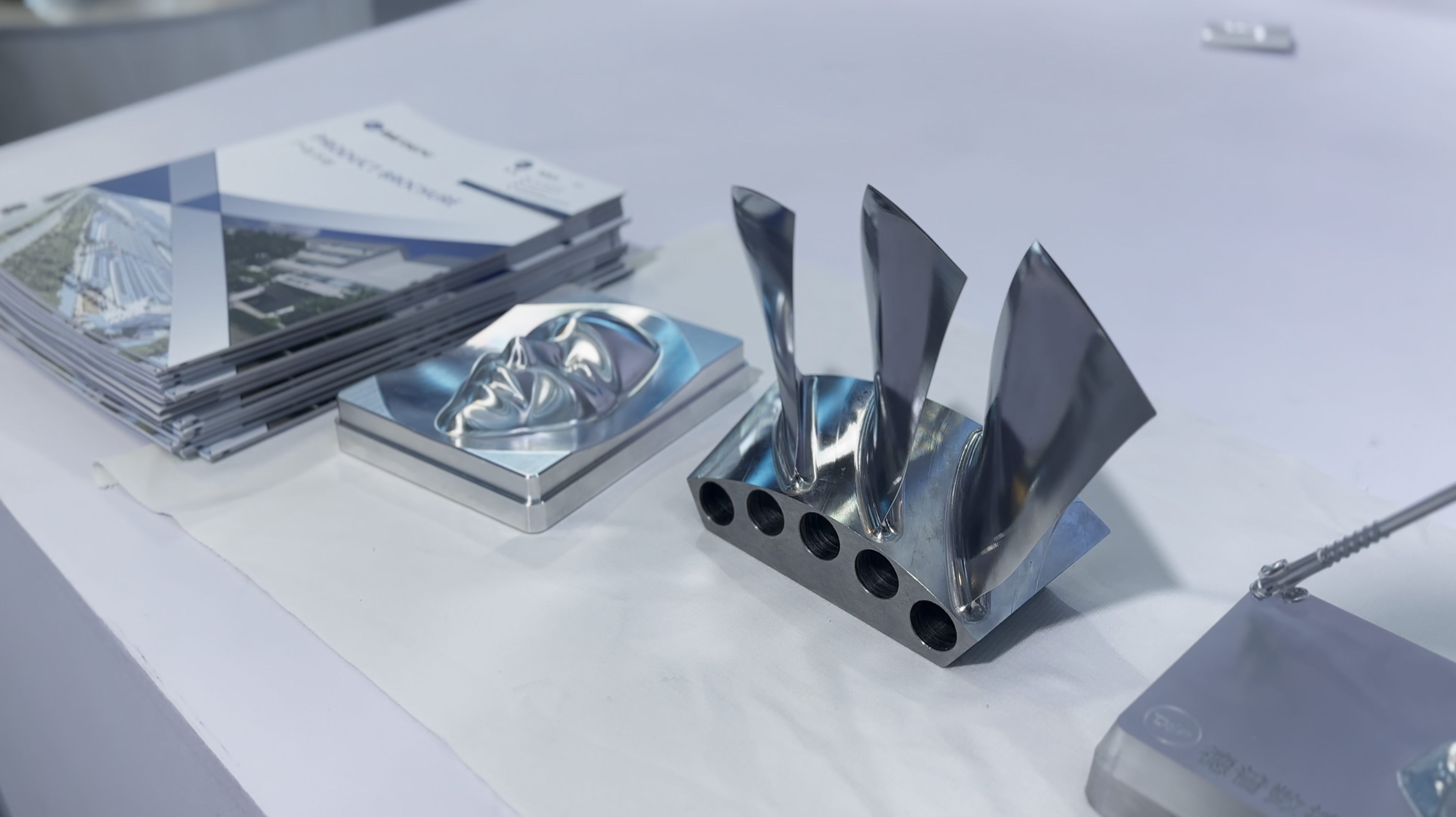

The versatility of 3D processing on 5 axes, or 3D обработка 5 осей, shines in producing detailed components with smooth surfaces and tight tolerances. Точная 5-осевая обработка is particularly valuable for crafting prototypes and end-use parts where every dimension matters. For instance, in 5-axis machining of parts, known as 5-осевая обработка деталей, our solutions support diverse materials from aluminum to titanium. DEPU provides turnkey installation and free custom fixture design, ensuring seamless integration into your workflow. This approach not only boosts productivity but also extends machine longevity by over 30% through our optimized engineering.

Integration in Mechanical Engineering

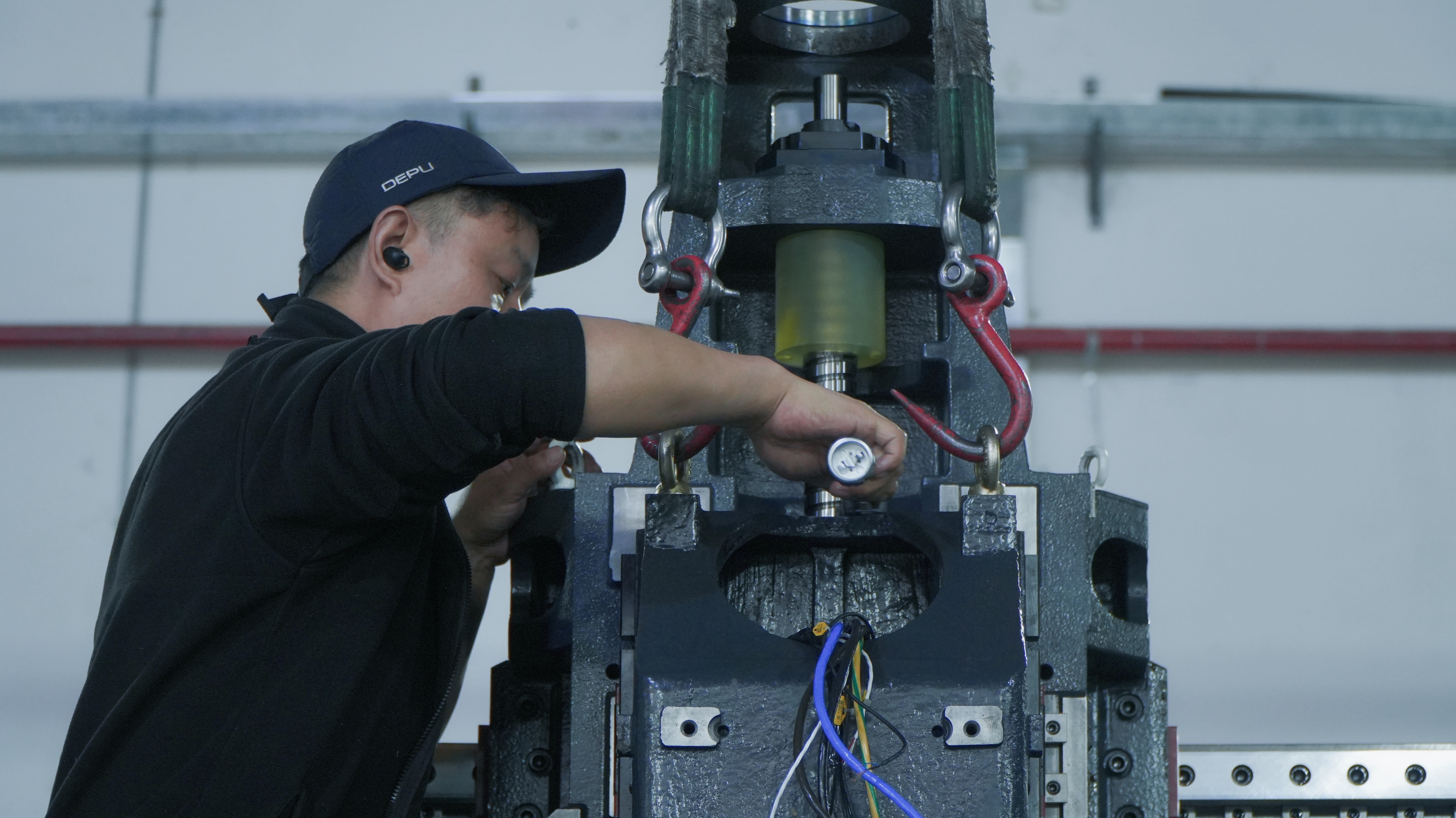

In mechanical engineering, 5-axis machining in mechanical engineering, or 5-осевая обработка в машиностроении, transforms how complex assemblies are fabricated. Methods of 5-axis machining, such as simultaneous multi-axis interpolation, allow for the creation of curved surfaces and undercuts without manual intervention. Our G and V series machines, enhanced in 2024, incorporate intelligent control systems for real-time monitoring, reducing cycle times significantly. Serving clients like 2 Fortune Global 50 companies, DEPU ensures end-to-end process control from prototyping to operational training, fostering innovation in ship equipment and 3C accessories production.

Advantages and Future of 5-Axis Technology

The advantages of 5-axis machining are manifold, including superior surface finishes, reduced tooling costs, and enhanced design freedom. Преимущества 5-осевой обработки make it indispensable for high-tech industries, where precision directly impacts performance and safety. At DEPU, our commitment to quality is certified by renowned clients and backed by a history of milestones, from launching our first-generation encoder in 2021 to unveiling the third-generation in 2025. As we continue to drive intelligent manufacturing, partnering with DEPU means accessing futuristic capabilities that redefine engineering paradigms, ensuring your projects achieve excellence with every machined detail.