Introduction to 5-Axis Machining

In the world of modern manufacturing, 5-axis machining stands out as a transformative technology that enables complex part production with exceptional precision. At DEPU CNC (Shenzhen) Co., Ltd., we specialize in delivering cutting-edge CNC machines that embody this innovation, helping industries achieve superior results. Our commitment to quality, backed by over 20 years of expertise, ensures that every 5-axis machining solution we provide meets the highest standards, from prototyping to full-scale production.

Understanding 5-Axis Metal Processing

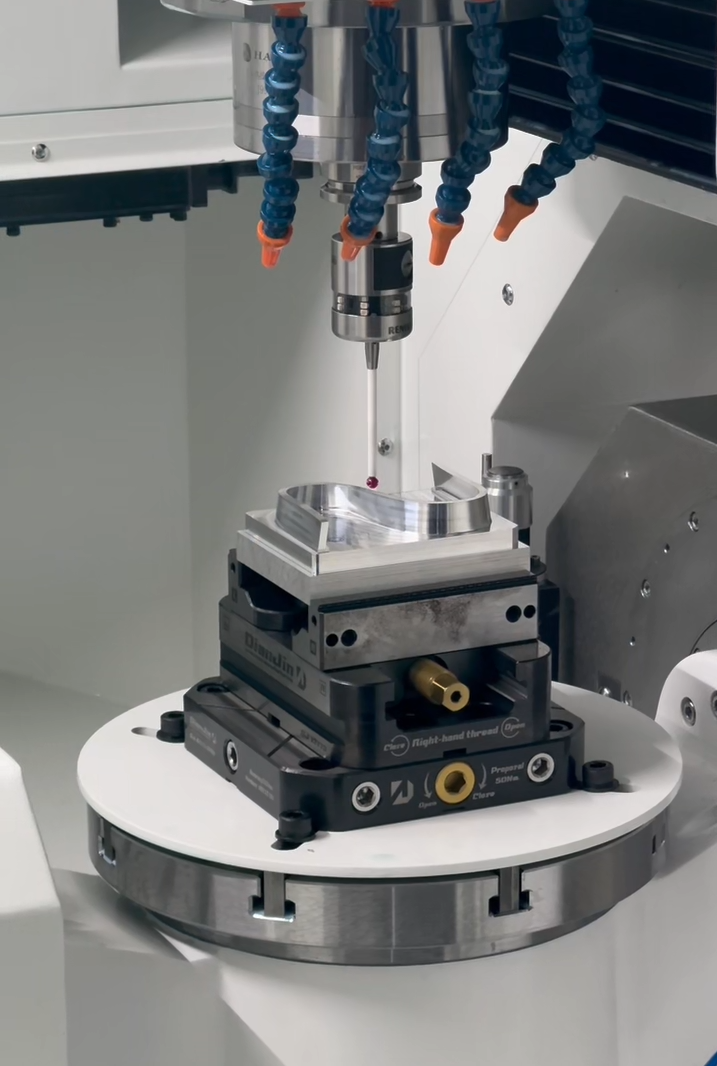

5-axis metal processing, often referred to as 5-axis machining, involves the use of advanced CNC systems to move a cutting tool or workpiece along five different axes simultaneously—three linear (X, Y, Z) and two rotational (A and B or C). This capability allows for intricate geometries that traditional 3-axis or 4-axis machines simply cannot achieve. At DEPU CNC, our machines feature wear-resistant alloys and reinforced structures, providing the stability needed for heavy-duty operations. For instance, in the automotive sector, 5-axis metal processing is crucial for creating high-tolerance parts like engine components that demand unwavering accuracy.

The process begins with detailed CAD/CAM programming, where engineers define tool paths to optimize material removal. Our Zeiss-validated precision ensures that each part maintains tolerances as tight as 0.001 mm, reducing waste and enhancing efficiency. Whether you're dealing with titanium alloys or aluminum, 5-axis metal processing minimizes setup times by allowing multiple operations in a single fixture, which is a game-changer for high-volume production lines.

Key Features of 5-Axis Milling Machines

5-axis milling machines are the backbone of this technology, equipped with high-speed spindles and automated tool changers that boost productivity. DEPU CNC's G-series and V-series models, optimized in 2024, exemplify this with their aerodynamically designed frames and modular components tailored for custom needs. These 5-axis milling machines handle everything from small 3C electronics accessories to robust ship equipment, all while integrating seamlessly with IoT platforms for real-time monitoring.

One standout aspect is the environmental efficiency; our systems include advanced dust and chip management to promote sustainability without compromising performance. Clients from Fortune Global 500 companies trust these machines for their longevity—extended by over 30% through innovative engineering—making them ideal for demanding applications in aerospace and medical device manufacturing.

Advantages of 5-Axis Machines in Precision Engineering

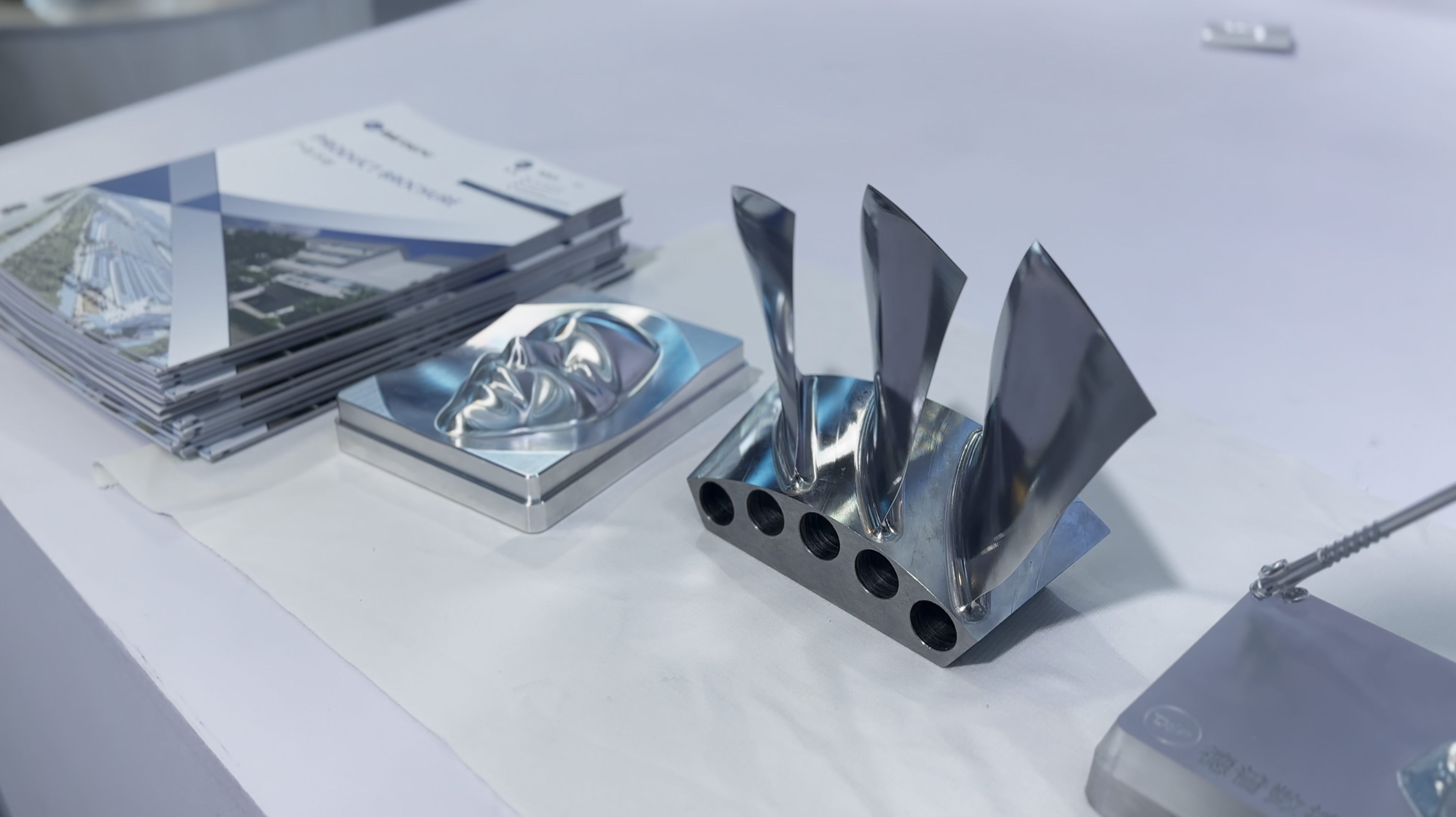

The advantages of 5-axis machines are manifold, particularly in achieving superior surface finishes and reducing machining time by up to 50% compared to conventional methods. At DEPU CNC, we offer turnkey installation and free custom fixture design, ensuring your transition to these 5-axis machines is smooth and productive. This technology excels in scenarios requiring complex contours, such as turbine blades, where undercuts and multi-angle cuts are essential.

Moreover, the precision validated by Zeiss CMM inspections guarantees reliability, fostering trust among our partners, including publicly listed companies. By minimizing vibrations and enabling high-speed operations, 5-axis machines not only enhance quality but also lower operational costs, aligning with our mission to drive intelligent manufacturing forward.

Applications of 5-Axis Processing in Mechanical Engineering

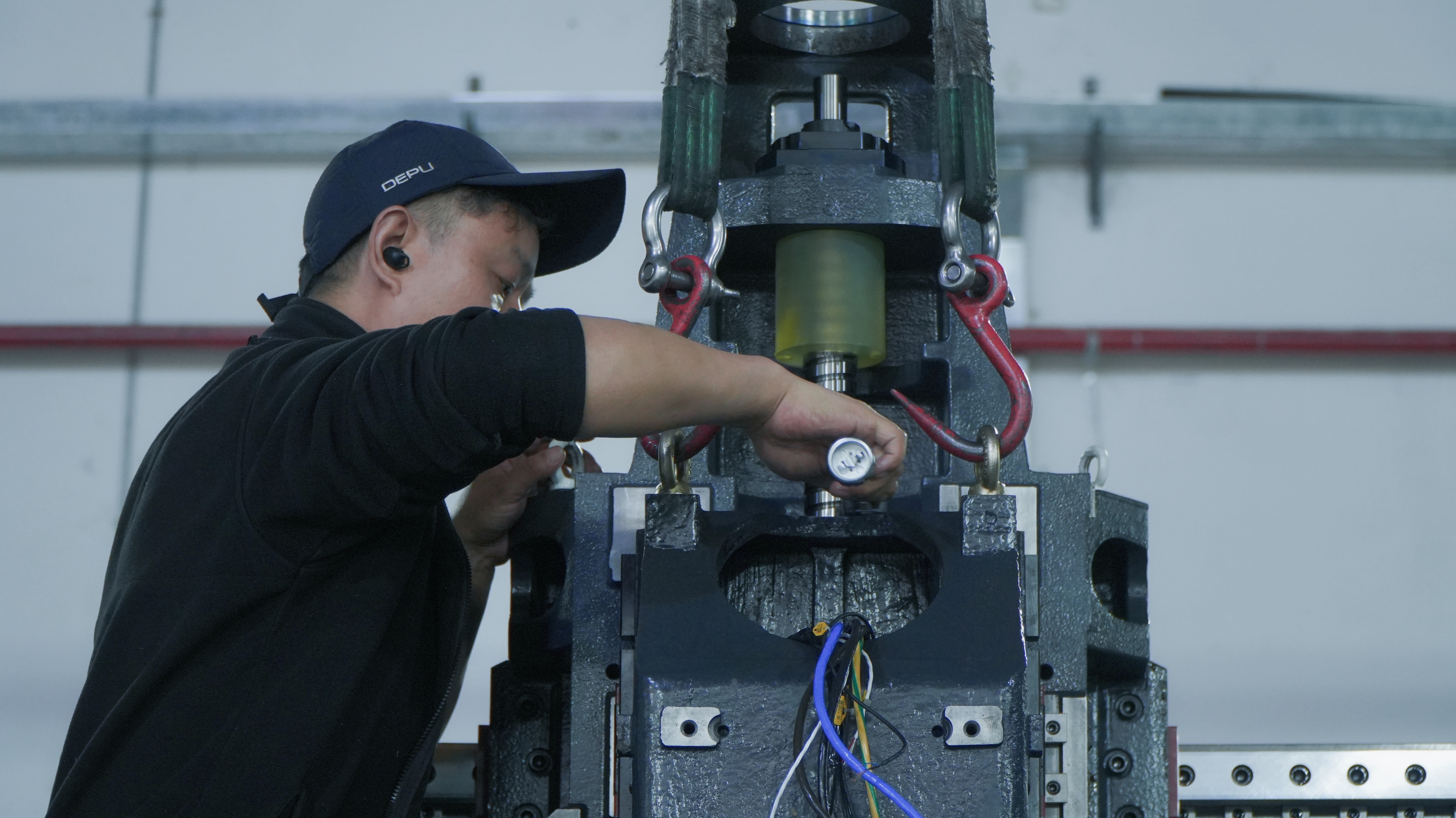

5-axis processing in mechanical engineering has revolutionized how industries approach part fabrication, from prototyping intricate prototypes to producing end-use components. Our U-series machines, debuted in 2024, support 3D processing across five axes, allowing for seamless creation of curved surfaces and deep cavities without repositioning. This is particularly beneficial in the shipbuilding industry, where corrosion-resistant parts must withstand extreme conditions.

DEPU CNC's end-to-end process control—from design to operational training—ensures that 5-axis processing in mechanical engineering delivers consistent results. We've served major clients with custom solutions, integrating advanced encoders inspired by principles of excellence, which enhance accuracy in dynamic environments.

Methods and Precise 5-Axis Processing Techniques

Methods of 5-axis processing vary based on the application, including simultaneous 5-axis milling for organic shapes and indexed positioning for hybrid workflows. Precise 5-axis processing, a hallmark of our offerings, leverages real-time feedback loops and high-resolution encoders to maintain micron-level accuracy. For 5-axis processing of parts, such as auto components or heat sinks, our machines reduce errors by eliminating multiple setups, streamlining workflows.

At DEPU CNC, we provide CNC programming services to customize these methods, ensuring optimal tool paths for materials like stainless steel or composites. Our 3D processing on five axes enables the fabrication of lightweight yet strong structures, vital for modern engineering challenges. With comprehensive support, including prototyping and advanced technology integration, we empower businesses to innovate without limits.

Why Choose DEPU CNC for Your 5-Axis Needs

Partnering with DEPU CNC means accessing a legacy of innovation since our founding in 2021, built on decades of R&D. Our machines not only embody the advantages of 5-axis processing but also align with global standards, serving elite clients worldwide. From the Depu-MasterLink automation system released in 2023 to our third-generation encoders planned for 2025, we're committed to pushing boundaries in manufacturing. Embrace 5-axis machining with DEPU CNC and transform your production capabilities today.

(Word count: 852)