Understanding Precision Mechanical Processing

Precision mechanical processing stands as the cornerstone of modern manufacturing, enabling the creation of components with unparalleled accuracy and reliability. At DEPU CNC (Shenzhen) Co., Ltd., we specialize in delivering high-end solutions that embody this expertise, drawing from over 20 years of R&D in CNC systems. Our commitment to innovation ensures that every project meets the stringent demands of industries like automotive, electronics, and marine applications. Whether you're seeking custom solutions or advanced prototyping, our turnkey services transform complex visions into tangible results.

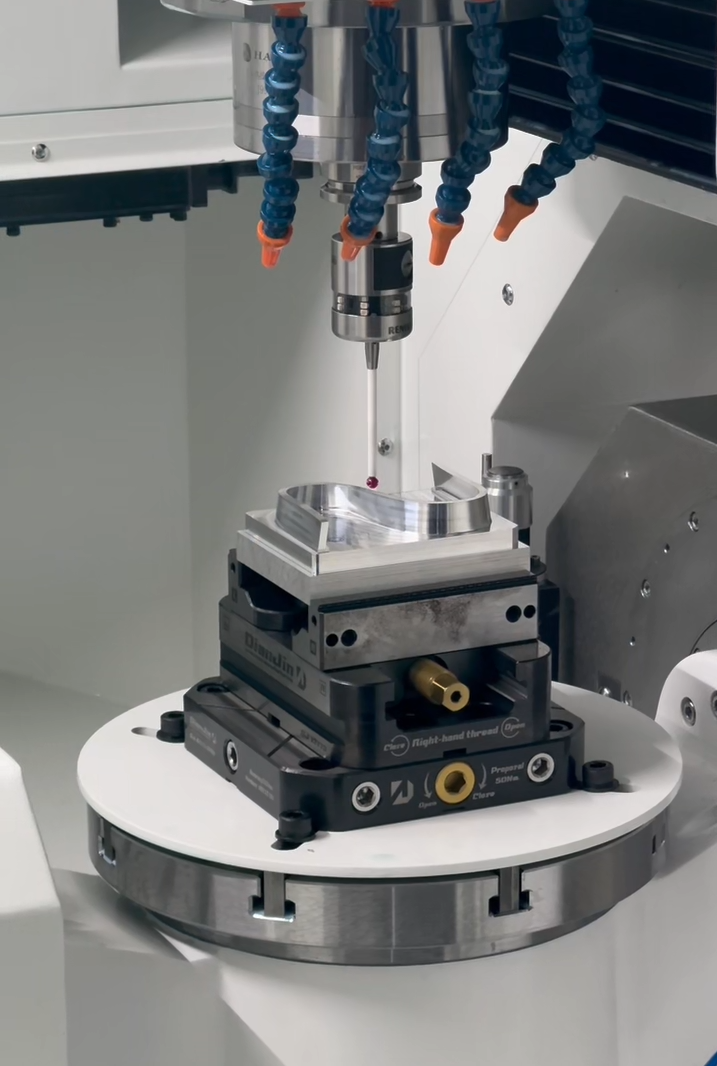

Essential Equipment for Precision Processing

Equipment for precision processing forms the backbone of efficient production lines, and our latest offerings at DEPU CNC exemplify this. Take the AIRCPHANE 202 BSC-54 NC, our state-of-the-art automated milling and drilling machine. This pinnacle of engineering features a high-performance spindle and advanced cooling system, allowing for seamless handling of diverse materials from metals to composites. With real-time monitoring via state-of-the-art sensors, it ensures every operation—from intricate drilling to high-volume milling—achieves micron-level accuracy. Paired with our wear-resistant alloys and Zeiss-validated inspections, this equipment guarantees longevity exceeding industry norms by over 30%, making it ideal for demanding environments. Clients from Fortune Global 500 companies trust our machines for their reliability and precision.

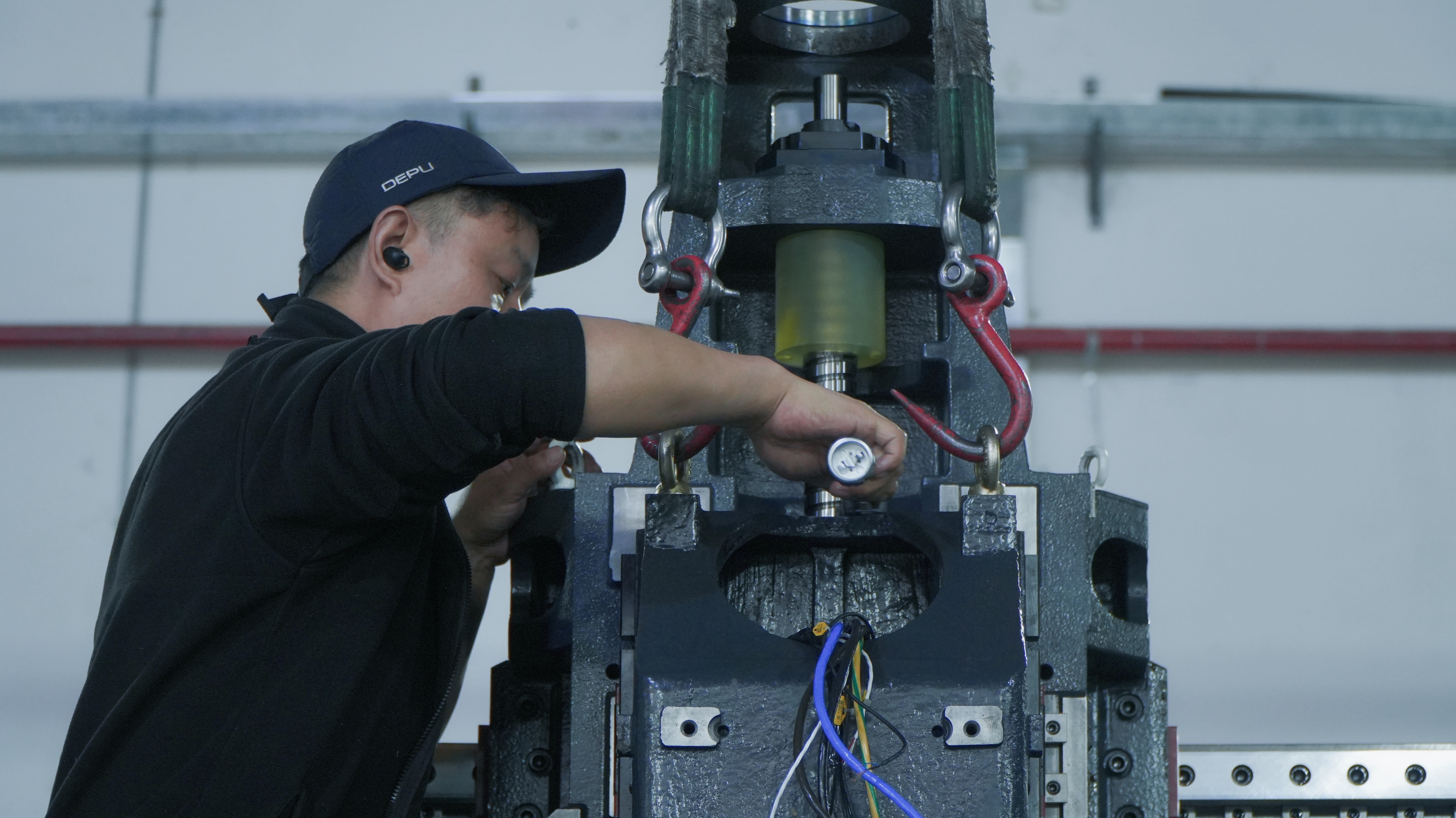

Comprehensive Services in Precision Mechanical Processing

Services for precision mechanical processing go beyond mere machining; they encompass end-to-end support tailored to your needs. DEPU CNC provides custom fixture design at no extra cost, alongside CNC programming and operational training, ensuring smooth integration into your workflow. Our high-tolerance parts, such as those for 3C accessories and auto components, are crafted using corrosion-resistant materials suited for extreme conditions. From prototyping to full-scale production, we monitor every stage with rigorous quality controls, serving renowned clients like publicly listed companies and Fortune Global 50 enterprises. This holistic approach not only enhances efficiency but also drives innovation, as seen in our timeline of advancements from the 2021 encoder launch to the 2025 third-generation enhancements.

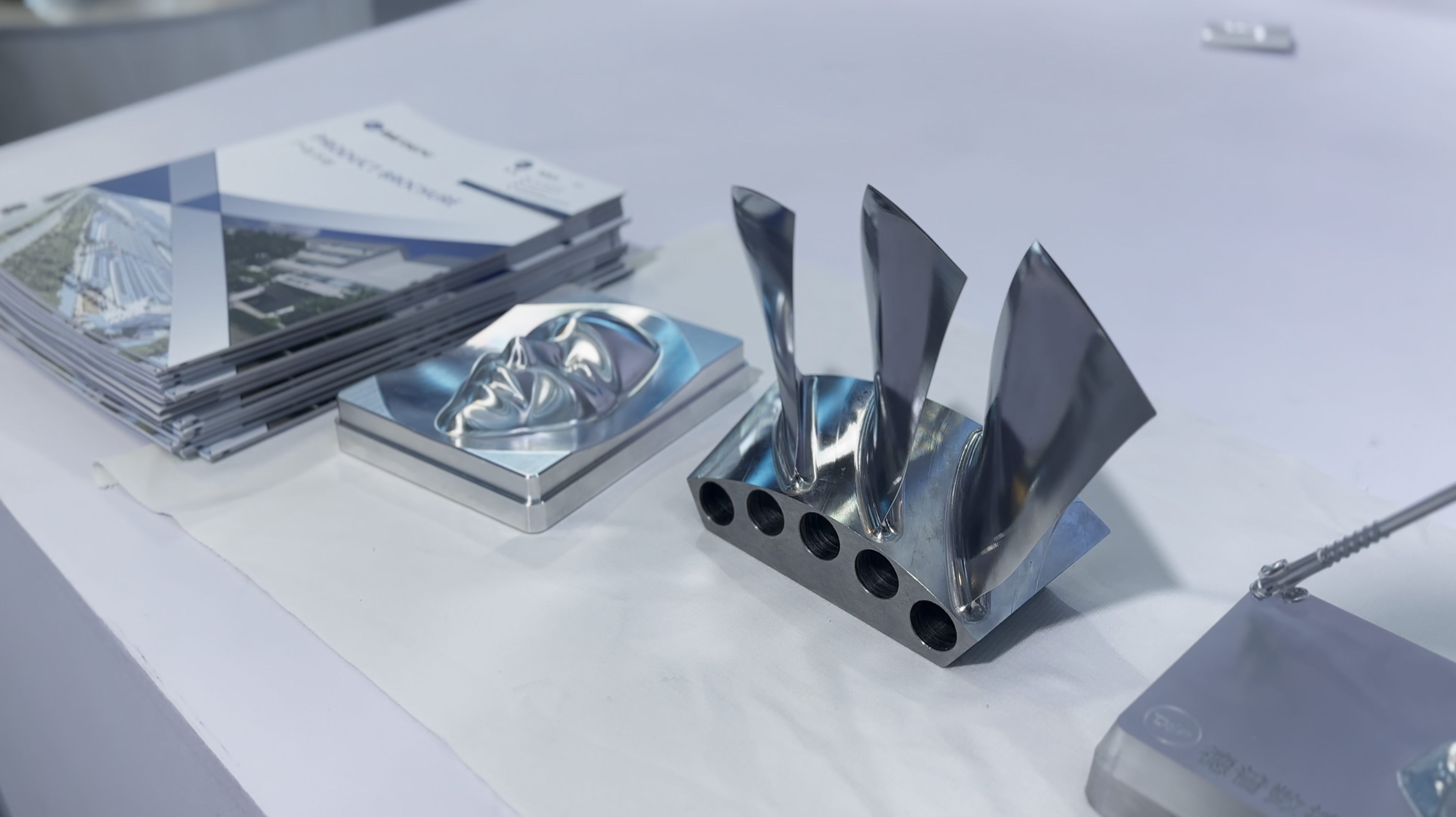

Precision Parts and Advanced Machining Methods

Precision parts demand meticulous attention to detail, and DEPU CNC excels in producing them through sophisticated methods of precision mechanical processing. Our Turbo Impeller, forged from mirror-finish titanium alloy, showcases intricately curved blades optimized via computational fluid dynamics for minimized turbulence and maximized airflow. These прецизионные детали are vital for high-performance turbo systems in racing or industrial applications, where every edge is polished to reduce drag without sacrificing strength. Technologies for precision processing, including our Depu-MasterLink automation, integrate seamlessly to handle complex geometries. For custom orders, our mechanical processing on demand delivers high-accuracy results, validated by CMM inspections, ensuring components meet exact specifications every time.

Technologies and Techniques for High-Accuracy Results

Technologies for precision processing evolve rapidly, and DEPU CNC leads with cutting-edge integrations like our G, V, and U series machines. Milling of precision parts, for instance, benefits from our intuitive interfaces and reinforced structures, enabling фрезерование прецизионных деталей with exceptional speed and clarity. High-accuracy mechanical processing techniques, such as those employed in our ship equipment solutions, incorporate advanced CAD and real-time adjustments to process сложных деталей flawlessly. Our 20+ years of expertise, inspired by principles of excellence, allow us to offer versatile solutions—from connectors in electronics to safety-critical auto parts. By prioritizing end-to-end process control and free custom tooling, we empower businesses to achieve superior output and longevity, redefining what's possible in manufacturing precision.

In summary, partnering with DEPU CNC means accessing a legacy of trusted innovation. Our services not only fulfill but exceed expectations, fostering growth through reliable, high-precision outcomes.